At UPM Conveyors we have over 40 years experience in designing, manufacturing and installing conveyor systems across a wide range of industries.

Recently we were delighted to work with W.E. Amies & Co Ltd, based in the UK. A technical injection moulding specialist, they were experiencing a high component temperature leading to distortion, as well as component damage during transportation on the belt.

Here we go into detail about the challenges our bespoke system resolved, which was installed to the complete satisfaction of the client, and used as part of their work manufacturing COVID-19 antibody test kits..

Contact us on 01753 548801 to discuss your requirements if you are currently experiencing similar problems. Our experts can create the best solutions for your business and offer excellent customer service.

The problem

- Component temperature above 50-degree Celsius causing distortion as they accumulate in the box

- Component damage during transportation on the belt

- High quality construction required for the conveyor using price competitive materials

- Labour intensive process with manual box change over

- Small footprint available for a solution

After discussion with the Amies Plastic Moulders to understand the issues, we used our expertise to create a conveyor system that would work better for their requirements.

Our solution

- Component temperature now ~30-degree Celsius to reduce distortion

- Low wear & FDA compliant modular link belt with side flights

- HMWPE conveyor sides, aluminium mobile support frame and PET-G dust covers

- Box accumulation system providing space for 1 off empty, 1 off filling and 1 off full box.

- Bespoke conveyor design using the latest 3D CAD software

After presenting our bespoke design, we manufactured and installed it on the premises and tested it’s functionality.

Conveyor 3D model

Our 3D model of the bespoke design, as presented to the client.

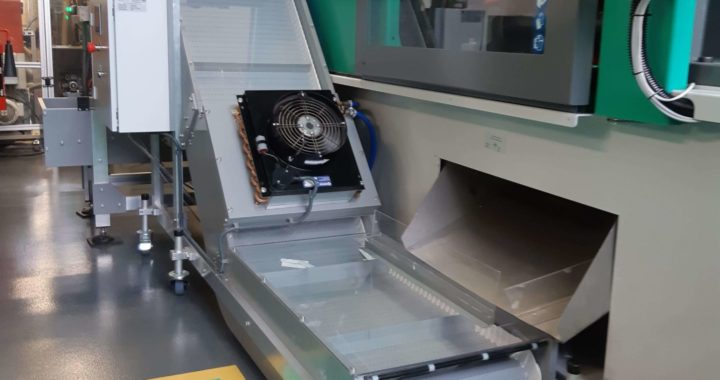

UPM Conveyor cooling system

- Two high efficiency fans (1ph 240v 0.6 amp) providing 1200 m3/h of air flow

- Air/heat exchangers requiring 10 bar chilled water with 15mm diameter pipes

UPM box accumulation and indexing system

Learn more about our box filling systems.

See this bespoke solution in action

Watch our YouTube video below to see our conveyor system for W.E. Amies & Co Ltd in action, with descriptions of each step it’s completing.

About W.E. Amies & Co Ltd

W.E. Amies & Co Ltd, or Amies Plastics, was founded in 1929 in Sheffield and is a trusted and successful plastics trade moulder, specialising in technical injection moulding for the engineering industry.

Speak to our team today

For more information on this recent project and to see how our expert conveyor solutions could benefit your business, please call 01753 548801 or email sales@upm.co.uk.

As an established company with over 1,600 clients using our products, we’re confident we can deliver the best results to benefit your company.